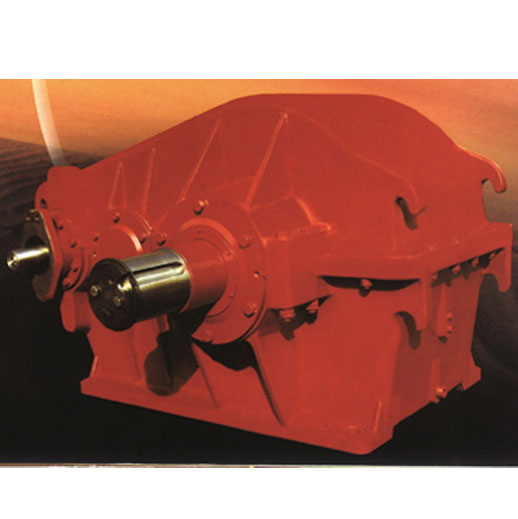

Gear Reducer jest niezależnym składnikiem składającym się z przekładni biegów, transmisji robaków i przekładni biegów zamkniętej w sztywnej skrzyni.Jest on często stosowany jako urządzenie przenoszące opóźnienia między częścią pierwotną a maszyną roboczą.Ma ona na celu dopasowanie prędkości i przenoszenia momentu obrotowego między napędem głównym, pracownikiem lub siłownikiem i jest powszechnie stosowana w nowoczesnych maszynach. 123567890 Możemy wykonać wiele rodzajów reduktora typu, takich jak typ Lufkin itp.Do reduktorów przekładni

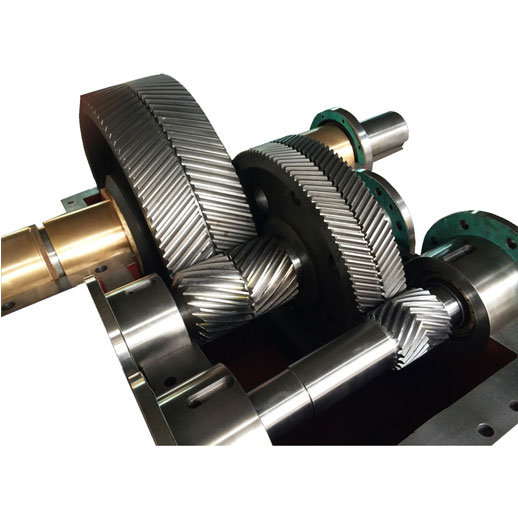

zalicza się przekładnie wykonane z zastosowaniem półproduktów ze stali wysokostopowej, zamiast standardowej stali odlewej.Narzędzia są cięte za pomocą 2-stopniowego procesu szorstkiego cięcia - obróbki cieplnej - wykończenia, co zapewnia głęboką penetrację procesu obróbki cieplnej głęboko w korzeniu zęba zęba zęba.GB w/ kute przekładnie stalowe zawiera 5-letnie "bez zadawania pytań" gwarancję

Model | 25D | 40 | 57 | 80 | 114 | 160 | 228 | 320 | 456 | 640 | 912 | 1280 |

Whole machine parameters | ||||||||||||

T(IN·LBS) | 25000 | 40000 | 57000 | 80000 | 114000 | 160000 | 228000 | 320000 | 456000 | 640000 | 912000 | 1280000 |

Transmission ratio(i) | 31.6 | 33.12 | 30.25 | 31.832 | 28.355 | 28.506 | 28.873 | 28.807 | 28.255 | 28.363 | 28.79 | 28.68 |

L | 850 | 935 | 1037 | 1080 | 1330 | 1480 | 1610 | 1830 | 1920 | 2010 | 2317 | 2713 |

L1 | 165 | 180 | 200 | 225 | 250 | 300 | 350 | 370 | 400 | 400 | 440 | 550 |

L2 | 235 | 270 | 300 | 325 | 400 | 450 | 500 | 580 | 600 | 650 | 790 | 900 |

L3 | 305 | 340 | 376 | 382 | 474 | 498 | 550 | 632 | 670 | 710 | 832 | 913 |

H | 517 | 592 | 666 | 668 | 825 | 875 | 978 | 1142 | 1220 | 1267 | 1514 | 1675 |

H1 | 270 | 310 | 350 | 350 | 425 | 450 | 500 | 590 | 650 | 660 | 785 | 840 |

H2 | 30 | 30 | 30 | 42 | 40 | 40 | 55 | 60 | 60 | 60 | 60 | 60 |

Base mounting hole | ||||||||||||

A | 630 | 695 | 760 | 750 | 1050 | 1177 | 1334 | 1510 | 1580 | 1668 | 2002 | 2040 |

A1 | 260 | 300 | 330 | 300 | 350 | 430 | 430 | 460 | 450 | 545 | 700 | 355 |

A2 | 250 | 275 | 330 | 340 | 510 | 530 | 540 | 620 | 650 | 605 | 620 | 620 |

A3 | / | / | / | / | / | / | 155 | 185 | 250 | 285 | 380 | 160 |

A4 | / | / | / | / | / | / | 55 | 59 | 67 | 70 | 103 | 110 |

A5 | 60 | 60 | 50 | 48 | 65 | 72 | / | / | / | / | / | / |

A6 | 115 | 115 | 165 | 170 | 175 | 175 | 270 | 310 | 395 | 350 | 370 | 310 |

A7 | / | / | / | / | / | / | / | / | / | / | / | 590 |

B | 420 | 470 | 460 | 510 | 700 | 750 | 780 | 880 | 1000 | 960 | 1375 | |

B1 | 360 | 400 | 396 | 450 | 635 | 670 | 680 | 770 | 900 | 860 | 890 | 1235 |

n-d1 | 6-Φ22 | 6-Φ24.5 | 6-Φ23 | 6-Φ24.5 | 6-Φ32 | 6-Φ32 | 8-Φ35 | 8-Φ39 | 8-Φ48 | 8-Φ48 | 8-Φ48 | 10-Φ50 |

Input parameters | ||||||||||||

d | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 400 | 400 | 400 | 500 | 600 |

Brake type | B | B | B | B | A | A | A | A | A | A | A | A |

h | 165 | 165 | 185 | 185 | 230 | 230 | 230 | 280 | 280 | 280 | 335 | 405 |

h1 | 150 | 150 | 165 | 165 | 215 | 215 | 215 | 265 | 265 | 265 | 315 | 380 |

h2 | 165 | 165 | 185 | 185 | 185 | 185 | 185 | 235 | 235 | 235 | 290 | 355 |

l1 | 250 | 250 | 250 | 250 | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 460 |

l2 | 145 | 145 | 144 | 144 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 130 |

d2 | 474.4 | 474.4 | 616.6 | 616.6 | 772.16 | 772.16 | 925.16 | 1027.16 | 1127.76 | 925.16 | 1280.16 | 1280.16 |

W1 | 296 | 324 | 314 | 343 | 387 | 427 | 445 | 521 | 605.5 | 585.5 | 626 | 855 |

W2 | 256 | 286.5 | 283 | 308 | 355 | 395 | 407.7 | 472.5 | 575.7 | 542.5 | 595.2 | 795 |

W3 | 42 | 61 | 80 | 80 | 85.7 | 111 | 111 | 136.5 | 136.5 | 162 | 187.3 | 187.3 |

Pulley groove | 2B | 3B | 4B | 4B | 3C | 4C | 4C | 5C | 5C | 6C | 7C | 7C |

Output parameters | ||||||||||||

W | 986 | 1066 | 1092 | 1170 | 1500 | 1640 | 1744 | 1920 | 2230 | 2189 | 2280 | 2905 |

C1 | 108 | 118 | 138 | 135 | 197.5 | 192 | 212 | 210 | 240 | 240 | 235 | 260 |

C2 | 105 | 113 | 135 | 135 | 190 | 188 | 205 | 205 | 235 | 235 | 230 | 255 |

Axle End Type | A | B | B | B | A | A | A | A | A | A | A | A |

D | 80 | 90 | 90 | 90 | 130 | 150 | 175 | 175 | 200 | 200 | 200 | 230 |

P | / | / | 50 | 45 | 60 | 60 | 70 | 70 | 110 | 110 | 110 | 110 |

M | / | / | 1/2" | 5/8" | 3/4" | 5/8" | 3/4" | 3/4" | 3/4" | 1" | 1" | 7/8" |

t | 71 | 79 | 81 | 81 | 119 | 138 | 160 | 160 | 185 | 185 | 185 | 210 |

b | 22 | 25 | 25 | 25 | 32 | 36 | 45 | 45 | 45 | 45 | 45 | 56 |

Wedge key① | C22×18×105 | C25×20×110 | C25×14×135 | C25×16×135 | B32×18.5×170 | C36×20.5×185 | C45×25.5×200 | C45×25.5×200 | C45×38.5×230 | C45×38.5×230 | C45×38.5×230 | C56×32×255 |

Note:①Wedge angle1:100. | ||||||||||||

szczelny typ maszyny typu

Model | FSL9 | FSL13 | FSL18 | FSL26 | FSL37 | FSL53 |

Parameter | ||||||

T(KN·M) | 9 | 13 | 18 | 26 | 37 | 53 |

Transmission ratio(i | 46.7 | 46.526 | 41.43 | 44.386 | 45.83 | 41.2 |

L | 1200 | 1265 | 1303 | 1475 | 1625 | 1945 |

L1 | 250 | 260 | 250 | 300 | 350 | 400 |

L2 | 350 | 378 | 400 | 450 | 500 | 600 |

L3 | 410 | 435 | 448 | 495 | 590 | 660 |

H | 738 | 781 | 834 | 910 | 1081 | 1170 |

H1 | 380 | 410 | 450 | 480 | 560 | 600 |

H2 | 45 | 38 | 40 | 50 | 47 | 50 |

Base mounting hole | ||||||

A | 845 | 900 | 940 | 1140 | 1230/920① | 1500 |

A1 | 360 | 400 | 410 | 500 | 400/150① | 510 |

A2 | 360 | 400 | 230 | 250 | 325 | 420 |

A3 | / | / | 180 | 250 | 325 | 420 |

A4 | / | / | 60 | 70 | 65 | 75 |

A5 | 55 | 50 | / | / | / | / |

A6 | 180 | 200 | 230 | 250 | 325 | 420 |

A7 | / | / | / | / | / | / |

B | 510 | 580 | 600 | 720 | 900 | 920 |

B1 | 450 | 510 | 520 | 620 | 770 | 830 |

n-d1 | 6-Φ26 | 6-Φ26 | 8-Φ33 | 8-Φ33 | 8-Φ33 | 8-Φ33 |

Input parameters | ||||||

d | 250 | 300 | 300 | 300 | 300 | 400 |

Brake type | A | A | A | A | A | A |

h | 205 | 230 | 230 | 230 | 230 | 280 |

h1 | 190 | 215 | 215 | 215 | 215 | 265 |

h2 | 160 | 185 | 185 | 185 | 185 | 235 |

l1 | 325 | 360 | 290 | 360 | 365 | 310 |

l2 | 110 | 110 | 110 | 110 | 110 | 110 |

d2 | 660 | 760 | 750 | 912 | 1050 | 1120 |

W1 | 349 | 385 | 395 | 452 | 470 | 563 |

W2 | 317 | 342.5 | 368 | 410 | 436 | 508 |

W3 | 65 | 85 | 85 | 100 | 100 | 117.5 |

Pulley groove | 3B | 4B | 4B | 5-15N/J | 5-15N/J | 6-15N/J |

Output parameters | ||||||

W | 1190 | 1300 | 1434 | 1570 | 1670 | 1840 |

C1 | 135 | 170 | 180 | 195 | 195 | 220 |

C2 | 135 | 170 | 177 | 190 | 195 | 220 |

Axle End Type | B | B | B | B | B | B |

D | 90 | 110 | 125 | 155 | 175 | 180 |

P | 45 | 50 | 60 | 70 | 90 | 100 |

M | M16 | M16 | M16 | M20 | M20 | M20 |

t | 81 | 100 | 114 | 142 | 155 | 160 |

b | 25 | 28 | 32 | 40 | 45 | 45 |

Wedge key② | C25×16×135 | C28×21×170 | C32×22×177 | C40×30×190 | C45×37×195 | C45×40×210 |

Note:①Different Sizes of Left and Right Sides of Base Installation Plate for FSL37;②Wedge angle1:100;③Other models of our company also adopt some or all anti-seepage technology.。 | ||||||

0531-69959201

lqg18653457231

+86 18653457231

Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română